What is gland packing? Gland packing, also known as stuffing box packing, is a type of mechanical seal used to prevent the leakage of fluids or gases from a rotating shaft or rod.

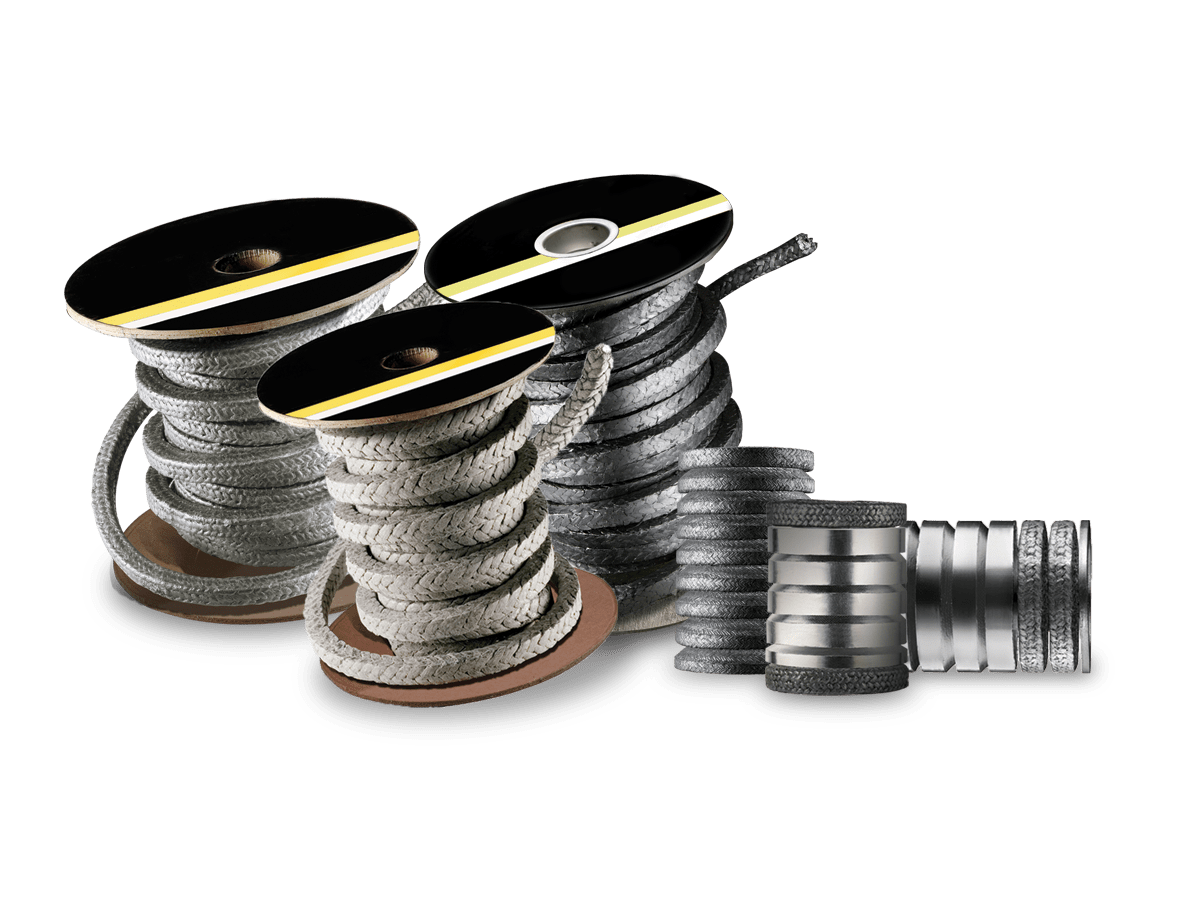

It is typically made of a flexible material, such as graphite, PTFE, or rubber, and is compressed around the shaft to form a seal. Gland packing is used in a variety of applications, including pumps, valves, and compressors.

The main benefit of gland packing is its ability to seal against a wide range of fluids and gases, including water, oil, and steam. It is also relatively inexpensive and easy to install and maintain. However, gland packing can wear out over time and may need to be replaced periodically.

In conclusion, gland packing is an important type of mechanical seal used to prevent the leakage of fluids or gases from a rotating shaft or rod. It is a relatively inexpensive and easy-to-use solution that can be used in a variety of applications.

What is Gland Packing?

Gland packing, also known as stuffing box packing, is a type of mechanical seal used to prevent the leakage of fluids or gases from a rotating shaft or rod. It is typically made of a flexible material, such as graphite, PTFE, or rubber, and is compressed around the shaft to form a seal.

- Material: Gland packing can be made from a variety of materials, including graphite, PTFE, rubber, and leather.

- Function: Gland packing is used to prevent the leakage of fluids or gases from a rotating shaft or rod.

- Applications: Gland packing is used in a variety of applications, including pumps, valves, and compressors.

- Installation: Gland packing is relatively easy to install and maintain.

- Cost: Gland packing is a relatively inexpensive type of mechanical seal.

- Lifespan: Gland packing can wear out over time and may need to be replaced periodically.

- Environmental impact: Gland packing can be made from environmentally friendly materials.

Gland packing is an important type of mechanical seal that is used in a variety of applications. It is a relatively inexpensive and easy-to-use solution that can be used to prevent the leakage of fluids or gases from a rotating shaft or rod.

Material

The material of gland packing is an important consideration, as it will affect the seal's performance and lifespan. Different materials have different properties, such as temperature resistance, chemical resistance, and wear resistance. For example, graphite is a good choice for high-temperature applications, while PTFE is a good choice for applications involving corrosive chemicals.

The choice of material will also depend on the specific application. For example, rubber gland packing is often used in water pumps, while leather gland packing is often used in steam engines.

In conclusion, the material of gland packing is an important consideration that will affect the seal's performance and lifespan. By choosing the right material for the specific application, engineers can ensure that the gland packing will provide a reliable seal.

Function

Gland packing is a type of mechanical seal that is used to prevent the leakage of fluids or gases from a rotating shaft or rod. It is typically made of a flexible material, such as graphite, PTFE, or rubber, and is compressed around the shaft to form a seal.

- Prevents leakage: Gland packing is designed to prevent the leakage of fluids or gases from a rotating shaft or rod. This is important in applications where leakage could be dangerous or costly, such as in pumps, valves, and compressors.

- Versatile: Gland packing can be used in a wide range of applications, including pumps, valves, and compressors. It is also compatible with a variety of fluids and gases, including water, oil, and steam.

- Cost-effective: Gland packing is a relatively inexpensive type of mechanical seal. This makes it a good option for applications where cost is a concern.

- Easy to install and maintain: Gland packing is relatively easy to install and maintain. This makes it a good option for applications where downtime is a concern.

In conclusion, gland packing is a versatile and cost-effective type of mechanical seal that is used to prevent the leakage of fluids or gases from a rotating shaft or rod. It is easy to install and maintain, making it a good option for a wide range of applications.

Applications

Gland packing is a type of mechanical seal that is used to prevent the leakage of fluids or gases from a rotating shaft or rod. It is typically made of a flexible material, such as graphite, PTFE, or rubber, and is compressed around the shaft to form a seal.

The applications of gland packing are varied and include pumps, valves, and compressors. In pumps, gland packing is used to seal the rotating shaft of the pump, preventing the leakage of fluid from the pump casing. In valves, gland packing is used to seal the valve stem, preventing the leakage of fluid from the valve body. In compressors, gland packing is used to seal the rotating shaft of the compressor, preventing the leakage of gas from the compressor casing.

The use of gland packing in these applications is critical to the proper functioning of the equipment. Without gland packing, fluids and gases would leak from the equipment, causing a loss of efficiency and potentially creating a hazardous situation. Gland packing provides a reliable and cost-effective way to prevent these leaks.

In conclusion, gland packing is an important component of pumps, valves, and compressors. It provides a reliable and cost-effective way to prevent the leakage of fluids and gases from these devices, ensuring their proper functioning and safety.

Installation

The installation of gland packing is a key aspect of its functionality and effectiveness in preventing leakage. The ease of installation and maintenance contributes to the overall practicality and cost-effectiveness of gland packing.

- Ease of Installation: Gland packing is designed to be straightforward to install, typically involving the compression of the packing material around the shaft or rod. This simplicity allows for quick and efficient installation, minimizing downtime during maintenance or repairs.

- Adjustable Sealing: Gland packing provides adjustable sealing, enabling the tightness of the seal to be modified as needed. This adjustability allows for fine-tuning the seal to achieve the desired level of leakage prevention while minimizing friction and wear.

- Maintenance and Replacement: Maintenance of gland packing is relatively easy, involving periodic inspection and tightening of the packing gland. Replacement of the packing material is straightforward and can be performed without the need for specialized tools or extensive disassembly.

- Cost-Effectiveness: The ease of installation and maintenance contributes to the cost-effectiveness of gland packing. Minimal downtime for installation and maintenance reduces labor costs, while the adjustable sealing allows for optimization of performance, extending the lifespan of the packing material.

In conclusion, the ease of installation and maintenance of gland packing is a significant advantage, contributing to its wide adoption in various applications. It allows for quick and efficient installation, adjustable sealing, straightforward maintenance, and cost-effectiveness, making it a practical and reliable solution for preventing leakage in rotating machinery.

Cost

The cost-effectiveness of gland packing is an important aspect of its widespread adoption in various industries. Its low cost compared to alternative sealing methods makes it an attractive option, particularly for applications where budget constraints are a concern.

The affordability of gland packing contributes to its practicality in numerous real-life applications. For instance, in water pumps, gland packing is a common choice due to its low cost and ability to effectively prevent leakage. Similarly, in industrial compressors, gland packing is employed as a cost-effective sealing solution, ensuring reliable operation and preventing gas leakage.

The cost-effectiveness of gland packing not only reduces initial investment costs but also contributes to long-term savings. Its ease of maintenance and replacement further minimizes operational expenses, making it a cost-efficient sealing solution over its lifespan.

In conclusion, the low cost of gland packing, coupled with its effectiveness as a mechanical seal, makes it a practical and economical choice for a wide range of applications. Its affordability contributes to its widespread adoption, providing a reliable and cost-effective solution for preventing leakage in rotating machinery.

Lifespan

The lifespan of gland packing is an important consideration for its use as a mechanical seal. Gland packing is designed to create a tight seal around a rotating shaft or rod, preventing leakage of fluids or gases. However, over time, the packing material can wear out due to friction, heat, and exposure to chemicals.

- Wear and Tear: Gland packing is subject to wear and tear during operation. Friction between the packing and the shaft or rod, as well as exposure to harsh chemicals or extreme temperatures, can cause the packing material to degrade. Regular inspection and maintenance are crucial to ensure optimal performance and prevent premature failure.

- Material Degradation: The material used for gland packing can also impact its lifespan. Different materials have varying degrees of resistance to wear, heat, and chemicals. Selecting the appropriate packing material for the specific application is essential to maximize the lifespan of the seal.

- Maintenance and Replacement: Regular maintenance, including tightening of the packing gland and inspection for signs of wear, is necessary to extend the lifespan of gland packing. Timely replacement of worn-out packing is crucial to prevent leakage and ensure continued effective sealing.

- Environmental Factors: Environmental factors, such as exposure to moisture, dust, or corrosive substances, can also affect the lifespan of gland packing. Proper installation and protection of the packing from harsh conditions can help prolong its service life.

In conclusion, the lifespan of gland packing is influenced by various factors, including wear and tear, material degradation, maintenance practices, and environmental conditions. Understanding these factors and implementing proper maintenance and replacement strategies are essential to ensure the reliable and effective performance of gland packing as a mechanical seal.

Environmental impact

The environmental impact of gland packing is a significant consideration, given the potential for leakage and the release of hazardous substances into the environment. Gland packing can be made from environmentally friendly materials, such as PTFE, which is non-toxic and chemically inert. This is important because it reduces the risk of environmental contamination and promotes sustainability.

The use of environmentally friendly gland packing materials is particularly important in industries where environmental regulations are stringent, such as the food and beverage industry. By choosing gland packing made from environmentally friendly materials, manufacturers can demonstrate their commitment to sustainability and reduce their environmental footprint.

In conclusion, the environmental impact of gland packing is an important consideration, and the use of environmentally friendly materials can help to reduce the risk of environmental contamination and promote sustainability. This understanding is crucial for industries that are subject to environmental regulations and for organizations that are committed to responsible manufacturing practices.

FAQs about Gland Packing

This section addresses frequently asked questions about gland packing, providing concise and informative answers to common concerns or misconceptions.

Question 1: What is gland packing used for?

Gland packing is a type of mechanical seal used to prevent the leakage of fluids or gases from a rotating shaft or rod. It is commonly used in pumps, valves, and compressors to ensure reliable operation and prevent environmental contamination.

Question 2: What materials are used in gland packing?

Gland packing can be made from a variety of materials, including graphite, PTFE, rubber, and leather. The choice of material depends on the specific application, considering factors such as temperature resistance, chemical resistance, and wear resistance.

Question 3: How is gland packing installed and maintained?

Gland packing is generally easy to install and maintain. It involves compressing the packing material around the shaft or rod and adjusting the packing gland to achieve the desired sealing. Regular inspection and tightening of the packing gland may be necessary to ensure optimal performance.

Question 4: What are the advantages of using gland packing?

Gland packing offers several advantages, including its versatility, cost-effectiveness, and ease of installation and maintenance. It can be used in a wide range of applications and is compatible with various fluids and gases. Additionally, gland packing is a relatively inexpensive type of mechanical seal.

Question 5: What are the limitations of gland packing?

Gland packing may have limitations in applications involving high pressures, extreme temperatures, or highly corrosive chemicals. It can also experience wear and tear over time, requiring periodic replacement to maintain effective sealing.

Question 6: How does gland packing contribute to environmental sustainability?

Gland packing can be made from environmentally friendly materials, such as PTFE, which is non-toxic and chemically inert. This reduces the risk of environmental contamination and promotes sustainability, particularly in industries with stringent environmental regulations.

Summary: Gland packing is a versatile and cost-effective mechanical seal with various applications in industries such as manufacturing, energy, and water treatment. Understanding its materials, installation, and maintenance requirements is crucial for ensuring optimal performance and preventing leakage.

Conclusion

Gland packing, a type of mechanical seal, plays a crucial role in preventing the leakage of fluids or gases from rotating shafts or rods. Its versatility and cost-effectiveness make it a widely adopted solution across industries, including manufacturing, energy, and water treatment.

The key points highlighted in this exploration of "what is gland packing" include its diverse applications, the range of materials used in its construction, and the importance of proper installation and maintenance. Gland packing can be customized to meet specific application requirements, ensuring reliable operation and minimizing leakage.

As technology advances, the development of new materials and innovative designs for gland packing holds promise for even greater efficiency, durability, and environmental sustainability in the future. By embracing these advancements, industries can continue to harness the benefits of gland packing for effective sealing solutions.

The Enduring Legacy Of Sherry Lewis And Lamb Chop

All You Need To Know About Electron Transport: A Comprehensive Guide

The Essential Guide To Cooking Corned Beef Without The Saltiness

Gland Packing

Cotton Gland Packing, Size 6 Mm To 38 Mm at Rs 150/kilogram in Kolkata

Gland Packing From A UK Leading Suppler Barnwell